Melnikov Press Fit Kit

A project by Daniel Cardoso Llach

Project Type: Generative Fabrication System, Generative Sculpture

Date: 2008

Keywords: Generative Fabrication, Konstantin Melnikov, Shape Grammars, Generative Sculpture, Press-fit kit

The series of new algorithmic 3-D models and physical prototypes introduced here originates in my observation of the intriguing dynamism of Konstantin Melnikov’s architecture, and of the computational nature of his design process. It builds on previous work on the definition of a “Melnikov Grammar” [3] that appropriated Melnikov’s design principles and formalized them in a set of two-dimensional rules (Melnikov’s principles operated always in two dimensions). I developed some early prototypes for the How to Make Almost Anything class at MIT.

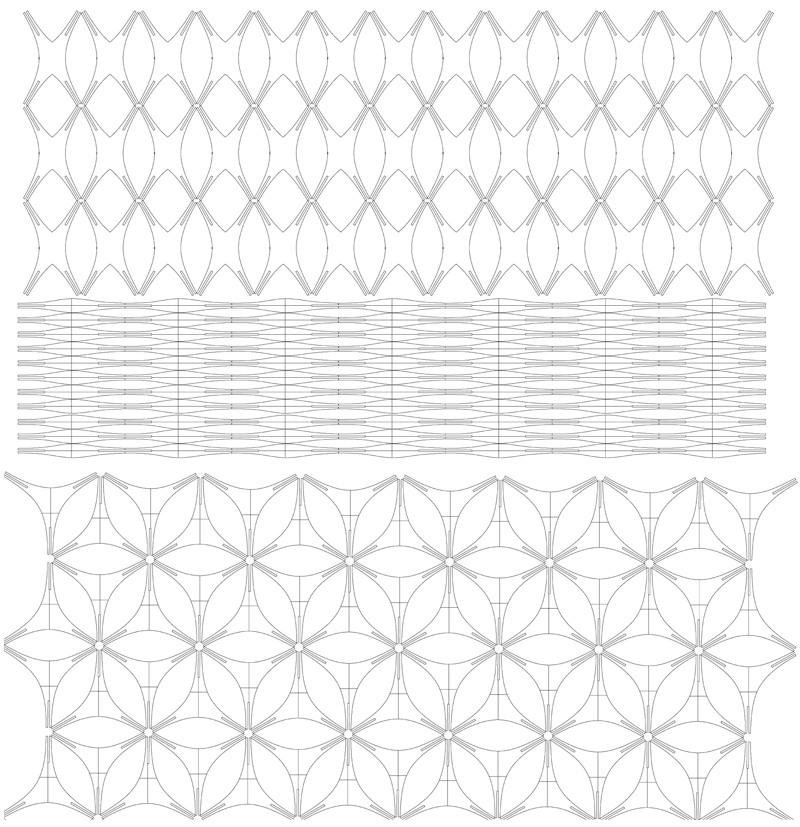

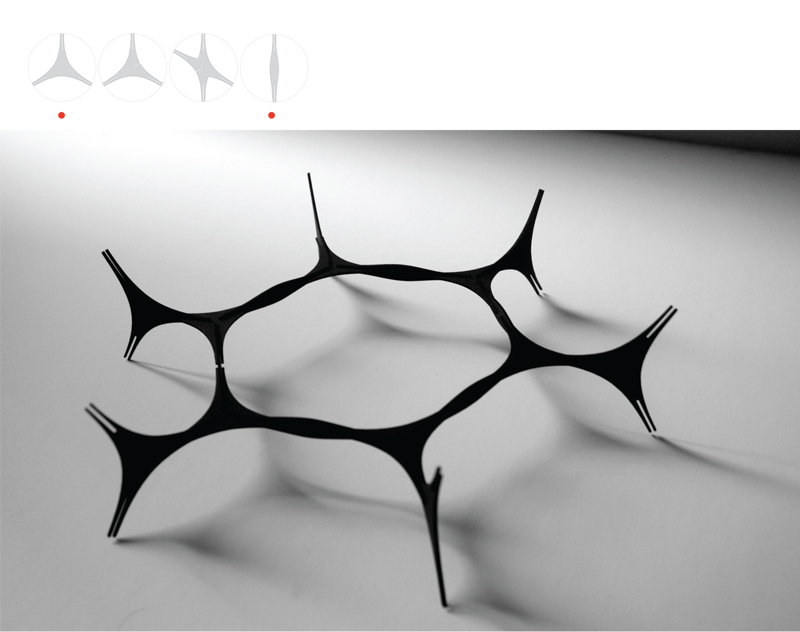

Figure 0. Melnikov Press Fit Kit Derivation

Among the architects and artists active during the second decade of the twentieth century in Russia, Konstantin Melnikov (1890-1974) stands as one of its most intriguing and exceptional. His work doesn’t sit comfortably with other examples of the period’s avant-garde, as it cannot be fully explained by the formal principles of Russian constructivism [1]. Some of his designs reveal instead a simple yet precise set of geometric elements and rules (addition, translation, subtraction and iteration) that configure an open-ended and rich formal language. In the light of this observation some examples of Melnikov’s architecture can be understood as having a particular generative –and computational!- logic. In other words, as the unfolding of a geometric –or shape- grammar [2]

Figure 1. Melnikov Grammar Press Fit Kit Cutsheet.

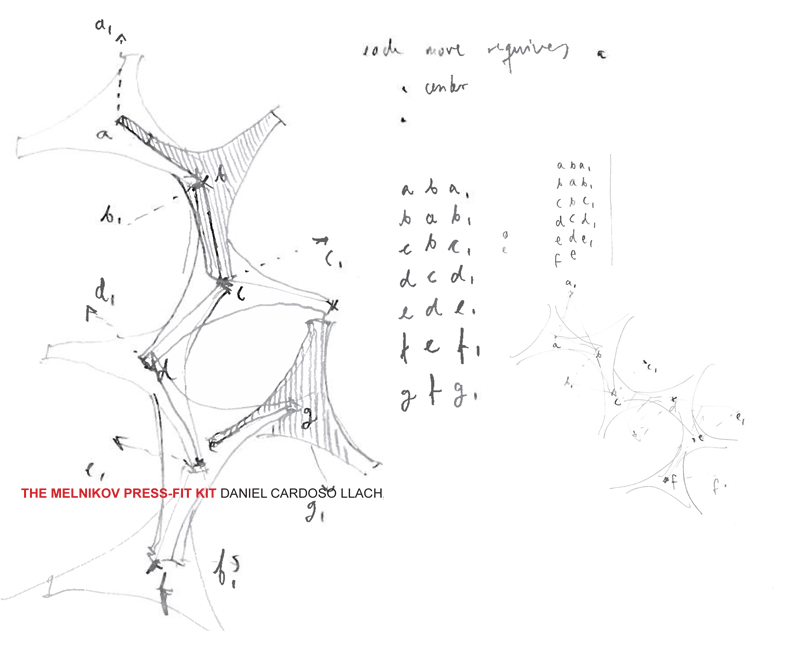

Figure 2. Melnikov Grammar early hand-drawn sketches

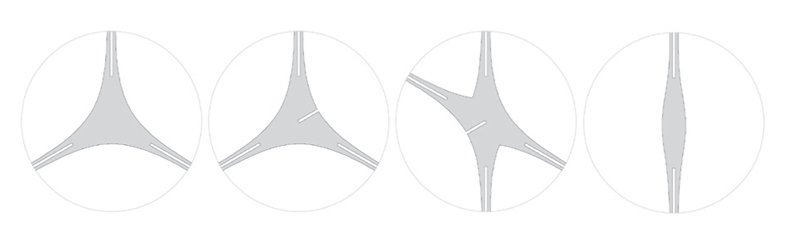

With the formalization, computational implementation and digital fabrication of a new 3-D grammar based on the “Melnikov Grammar” the work here presented discovers unexpected spatial, material and structural effects and documents the prototypes’ performance in terms of (i) a-periodic variation of spatial units and (ii) Extensible structural modules that self-adjust for error. Some limitations in the prototype’s scalability and structural performance are also discussed. By involving an architectural-historic inquiry into Melnikov’s work in a digital-fabrication exploration the “Melnikov Press-Fit Kit” seeks to re-specify traditional conceptions of digital fabrication as a “digital-to-material” endeavor into an explicit “cultural-digital-material” generative loop. As such, the “Melnikov Press-Fit Kit” is used as a vehicle for discussing aspects of digital fabrication and its relationship to authorship, automation and geometry.  Figure 3. Grammar Members

Figure 3. Grammar Members

The Press Fit Kit

A new version of the grammar is defined by transforming the cylinders into modules of 2 and 3 friction joints and by having each transformation rule alternate planes between the XY and YZ planes relative to each element’s friction-joint axis. This operation opens a completely different range of formal expression. The dependency relationships between different elements in the grammar define the way the propagation of variation takes place as a function of accumulation and growth.

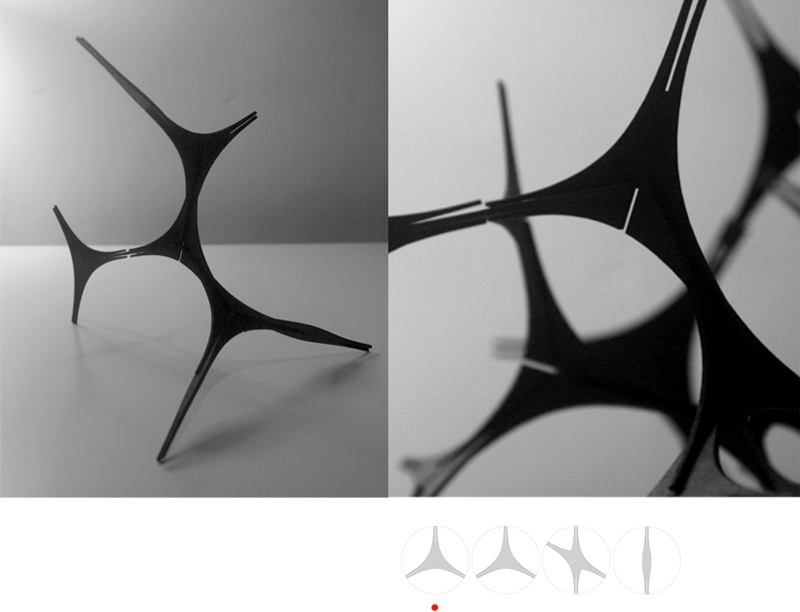

Figure 4. Early 3D Sketches

Figure 5. Simple Derivations

Figure 6. Physical Derivation Prototypes (red dots indicate members used)

Figure 6. Physical Derivation Prototypes (red dots indicate members used)

Figure 7. Physical Derivation Prototype

Figure 8. Melnikov Grammar Press Fit Kit Derivation

Two kinds of physical prototypes were developed. A set of small prototypes was used to quickly test the formal qualities of the grammar and a larger one designed to test the scalability of the system. The small prototypes were built using a 50W laser cutter on 1/32” cardboard. The larger modules were built using a Shopbot CNC router on sheets of 48x48, ½ in thick plywood. The prototypes showed how the rigidity of systems built with the kit increased as more modules were added because each module introduced new geometric constraints in the system.

Figure 9. Automatic Derivation of the Melnikov Grammar Press Fit Kit

A parametric model was built in Digital Project V.4 to enable local change at the element level and test different values such as thickness, material and tolerance [See attached Figures]. Additionally a plug-in written in the RhinoScript language –a scripting language that enables automation of Rhinoceros’ geometric functions -was developed to quickly test more complex derivations of the grammar. These were key for discovering an important discrepancy between the digital and physical representations of the grammar.

Figure 10. Automatic Derivation of the Melnikov Grammar Press Fit Kit

Error Correction

The discrepancy arised from the accumulation of error caused by the variation in the distance of members resulting from the shift from XY to the YZ planes in the alternation rules. While this discrepancy is also present in the physical models, it is absorbed by the materials’ flexibility, making it hard to detect. The discrepancy problem was problematic for the digital models produced with the script, yielding a number of un-buildable forms [See Figures], but in fact useful for the physical ones: the elements would adapt to the stress of adjacent elements, giving the global structure an unexpected robustness. The process of assembly thus resembles weaving more than a linear stacking of elements, demanding both flexibility and elasticity from the materials.

Figure 11. Derivation

Next Steps

1_ Accounting for the local-to-global deformations: while the behavior of a single piece is relatively easy to model an assembly comprising several pieces rapidly becomes a multi-constrained system. Each new element adds new constraints to the system, which means that the accuracy of the model depends on the ability to account for the accumulation of local stresses and bending. Developing a modeling strategy for the overall deformation of 3-D derivations of the Press-Fit Melnikov grammar is thus a next step.

2_ Researching Materials for scalability: While the models built with flexible materials such as wood or paper were easy to assemble the prototypes developed using ½ in thick plywood were not able to “close” in the same way. [See Figures] Research on flexible materials and FEM is required before bringing the kit to larger scales and potentially using its derivations for full-scale structures.

Figure 12. Testing for tolerance

3_ Exploring geometric gradients: The Kit’s potential to articulate a-periodic spaces can be increased if variability in the elements is considered. The angle Æ between elements can become a dependent variable and thus adding variability to the structure, provided flexible materials.

Conclusion

The contingencies of physical materials are often hard to predict in digital design to fabrication endeavors. These contingencies often conceal structural and expressive opportunities worthy of investigation. By involving cultural, material and digital concerns, the Melnikov Press-Fit Kit takes advantages of such discrepancies and becomes the vehicle of an ongoing design exploration.

Figure 13. 1/2 in plywood derivation of the Melnikov Grammar

With the support of the MIT MedialLab’s Center for Bits and Atoms and at the MIT Department of Architecture.

References

[1] Pallasmaa, Juhani and Andrei Gozak: 1996, The Melnikov House, Academy Editions, Singapore.

[2] Stiny, G and Gips, J: 1978: Algorithmic Aesthetics: Computer Models for Criticism and Design in Arts. University of California Press, Berkeley and Los Angeles, California.

[3] See also: Cardoso, D., & Nagakura, T. (2008). The Melnikov Grammar. 3A International Conference of Computer Graphics and Artificial Intelligence. Athens.

[4] Nagakura, Takehiko 2006, Advanced Topics in Design and Computation: Implementing a small Top-down Grammar. Unpublished.

[5] Stiny, George: 1980, Kindergarten Grammars: designing with Froebel’s building gifts. Environment and planning B 7(4): 409-462.

daniel cardoso llach - all rights reserved